Peace of Mind

Cost-Cutting Benefits

Future-driven component solutions with cost-effective advantages. Pioneering dry vacuum and turbo molecular pumps with integrated gas abatement systems.

Components and Applications

Our wide range of pump models and gas abatement systems.

|

Ashing Atomic Layer Deposition (ALD) Chemical Vapor Deposition (CVD) Diffusion Epitaxy Etch Processes Ion Implant Lithography-Metrology Load Lock Vacuum Micro Machining (MEMS) Physical Vapor Deposition (PVD) Rapid Thermal Processing (RTP) Residual Gas Analysis Silicium Technology Sputtering Surface Analysis |

Coating Flat Panel Display (FDP) Industry Leak Detection Systems Machine Tooling Magnetic Media Medical Engineering Vacuum Drying |

Analytical Tools Electric Gravometrics Mass Spectrometres Microsopy Osmometrics XPS |

Biotechnology Elementary Particle Physics Nanotechnology Nuclear Fusion Particle Accelerator Plasma Research |

Atomic Layer Deposition (ALD) | LED Manufacturing |

Fluoroproducts Industrial Chemical Productions Oxidation of Pyrophoric Gases Special Chemistry |

|

| Semiconductors | General Vacuum | Analytical Instruments | R & D | Photovoltaic | LED | Chemical Industry | |

| EV-A | |||||||

| EV-S | |||||||

| EV-L | |||||||

| EV-M | |||||||

| EV-PA | |||||||

| EV-SA | |||||||

| ESR | |||||||

| EST | |||||||

| ESA | |||||||

| G5 | |||||||

| G6 | |||||||

| TND | |||||||

| Dynox | |||||||

| EMT | |||||||

| EMT-MK | |||||||

| EBT | |||||||

Explore Comprehensive Components and Solutions

Innovative Components for Enhanced Industrial Performance and Efficiency

Discover our extensive range of components and solutions meticulously designed to meet the stringent demands of engineers across various industries. In this article, we will delve into the world of components, providing insights into what they are, their crucial role, different types, reliability, and the importance of selecting the right components for specific applications, all while ensuring sustainability and energy efficiency.

An Introduction to Components

EBARA’s components represent the pinnacle of engineering tailored to industrial requirements. They play a pivotal role in ensuring precision, reliability, efficiency, and environmental stewardship across various industrial processes. Engineers rely on them for their ability to enhance overall system performance, achieve operational excellence, and reduce ecological footprints.

Understanding Our Component Offerings and Their Crucial Roles

Our portfolio includes a wide range of components designed to cater to diverse industrial needs while promoting sustainable practices:

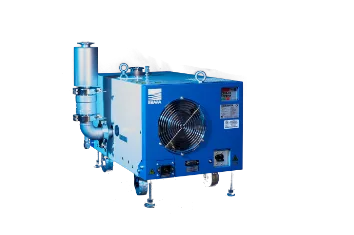

Dry Vacuum Pumps:

Dry Vacuum Pumps provide oil-free operation crucial in industries where contamination is a concern, designed with energy-saving capabilities. They find applications in semiconductor manufacturing, food packaging, and pharmaceutical production, ensuring robust, reliable, and energy-efficient vacuum generation.

Turbo Molecular Pumps:

Turbo Molecular Pumps, vital for applications requiring ultra-high vacuum conditions, also focus on energy efficiency. They serve scientific research, thin-film deposition, and analytical instrumentation, excelling in providing precision, reliability, and reduced power consumption.

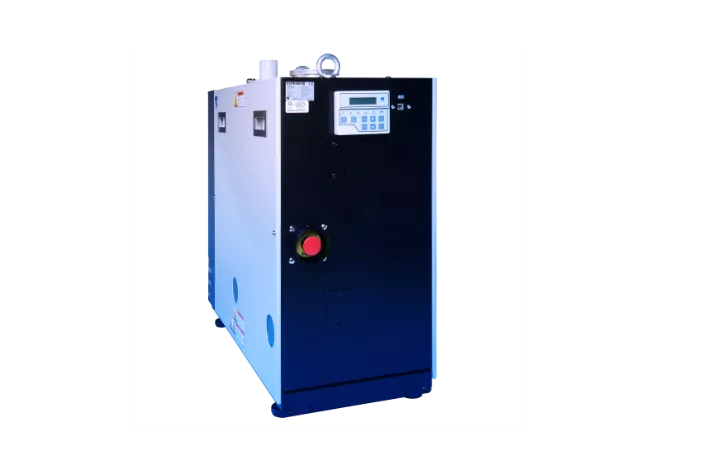

Gas Abatement Solutions:

Gas Abatement Solutions capture, treat, and neutralize harmful gases emitted during industrial processes, safeguarding both the environment and personnel. They play a crucial role in sustainable industry practices, mitigating the impact of volatile organic compounds (VOCs), hazardous chemicals, and other pollutants.

Integrated Solutions:

Integrated Solutions combine dry pump technologies with advanced gas abatement capabilities in an energy-efficient package. They offer efficient and reliable gas abatement alongside dry pump technologies, maintaining clean and oil-free vacuum environments with minimal energy usage.

Engineering Services:

Our Engineering Services provide comprehensive support, ensuring the successful integration and operation of components with an eye on sustainability. We work closely with engineers to tailor solutions that meet their specific requirements and enhance energy efficiency.

Reliability, Performance, Sustainability, and Versatility

These components are engineered for reliability and top-notch performance, with a focus on sustainability. They guarantee steady operation over time, reducing the risk of unexpected downtime and significantly enhancing overall process efficiency and environmental responsibility. Their versatility across a range of industrial applications is a testament to their adaptability and commitment to green engineering principles.

Choosing the Right Components

Selecting the correct components is pivotal for achieving operational success, efficiency, and ecological conscientiousness. Whether you require the cleanliness of a Dry Vacuum Pump or the precision of a Turbo Molecular Pump, products are available to meet your specific needs. Gas Abatement Solutions and Integrated Solutions enhance environmental compliance and workplace safety, while Engineering Services ensure seamless integration and operation with sustainability as a core objective.

Success Story

Efficient, smart and green.

Vaccum solutions for coating systems to produce ultra-thin modules for solar energy.

Read More

EBARA Worldwide Brand Movie

Since 1912 EBARA is dedicated to drive the future of vacuum and semiconductor systems.