Enhanced Mask Plating

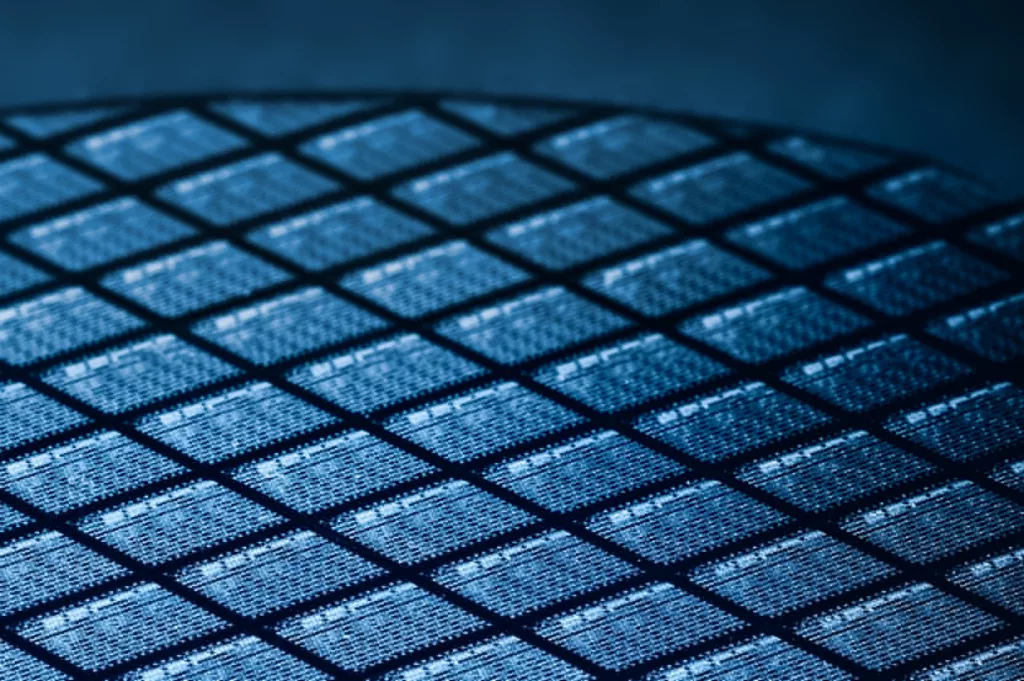

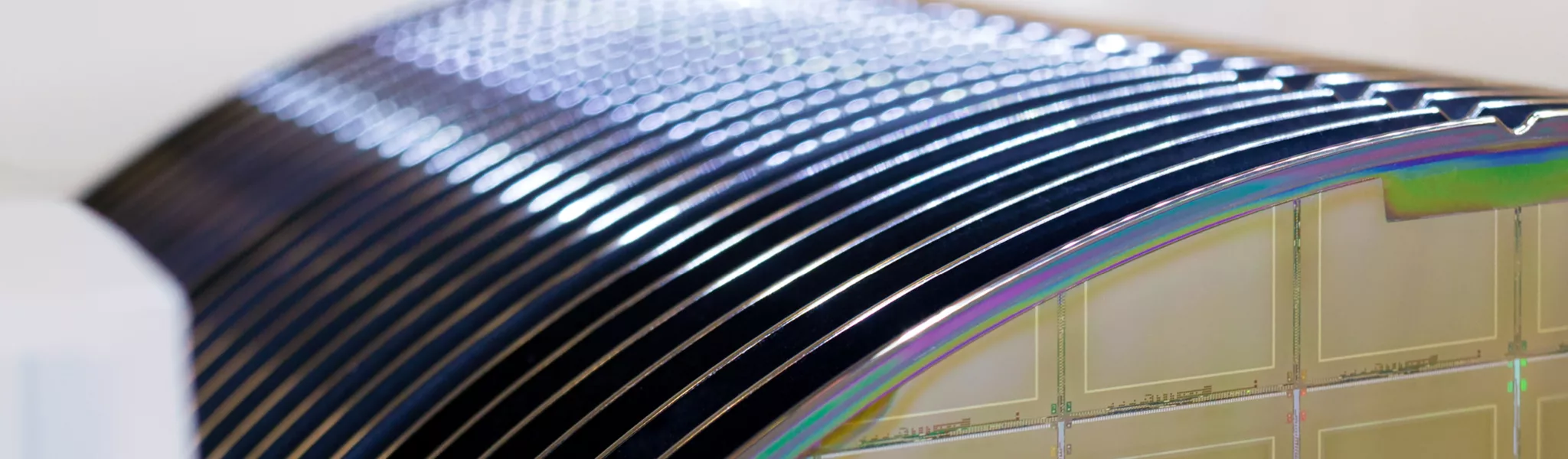

The wafer plating systems enable fast, high performance processing for depositing fine conductive patterns on wafers. This includes bumps, pillars, re-wirings and through silicon via structures, which are essential for packaging techniques.

Core Benefits

Applications for UFP Models

- Redistribution

- Bumping

- IC Advanced Packaging

- Wafer Level Chip Packaging

- Multi-layer Applications

- Patterned Plating (Copper, Nickel, Gold, Solder)